Rely on the Building Science Experts

Nobody understands the science of building better than . If you want to create a thermally efficient and air tight space, it's not enough just to insulate. You must choose the right insulation and air sealing system for the application, and be sure it's properly installed.CLICK FOR DETAILS

LET. US. HELP.

Spray Foam Insulation in the Attic (Non-Vented Attic Spaces)

In this application, considered the most effective, by most of the SPF industry, the foam is sprayed directly to the underside of the roof between the joists, down around the rim and into the soffit areas, on the gable wall ends, and effectively sealing off and insulating the entire attic space from any air infiltration.

By now you have probably heard of this procedure with terms like: "Hot Roof design", Unvented Attic, Conditioned Attic, or "The Insulated Envelope."

We at use the term "Unvented Attic."

Energy Savings

A vented attic situation will become approximately 130-140 degrees in the summer. There's no reason for your air-conditioning and vent-ductwork to have to work in that type of severe conditions. There is also opportunity for moisture to form due to condensation on these appliances

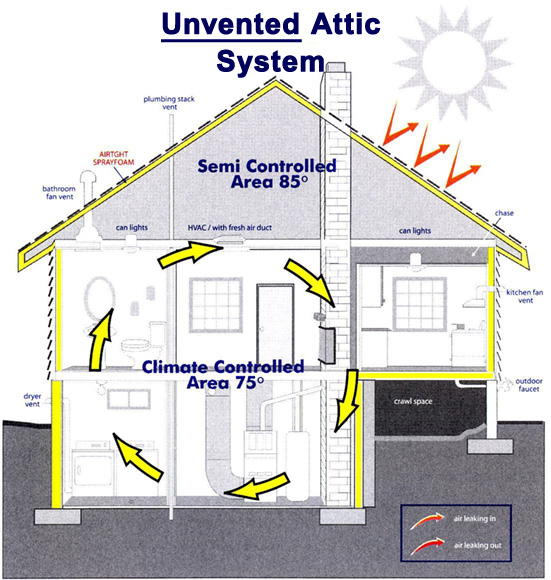

By applying spray foam directly to the underside of the roof deck, it now insulates the attic space from the extreme heat that once radiated thorough the hot shingles sheathing and roof. The severe temperatures no longer exist in the attic. In short, the attic now becomes a passively "conditioned" space of the house that is just as comfortable as any other room in the home.

A roof system insulated with spray foam reduces energy several ways. Energy loss from ducts located in the attic is essentially eliminated. The top of the building is much tighter resulting in less infiltration and exfiltration, so excess moisture isn't pulled into the attic. Infiltration through the ceiling is also reduced. In addition, the attic temperature is remarkably lower, which further reduces energy loads.

Conduction, Convection and Radiant Heat Transfer

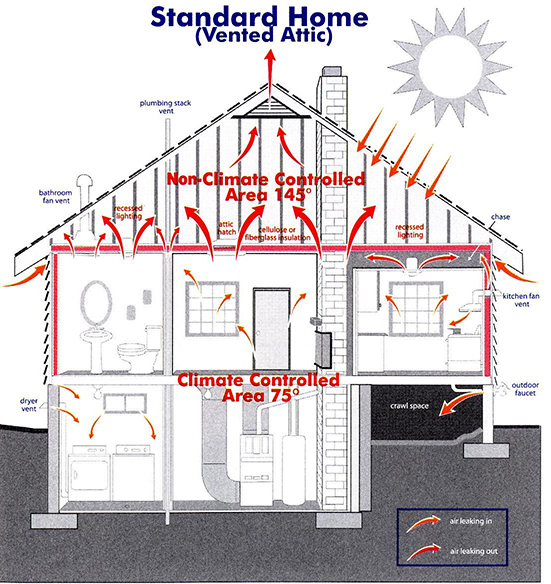

In a standard insulation system, ceiling insulation reduces the transfer of heat from the attic to the living space (in the summer). Attic temperatures can often approach 140 degrees or more during the day. Most of this heat enters the attic space through a multi-step process.

First, solar energy warms the shingles and sheathing. The hot sheathing then transfers heat to the rest of the attic through conduction, convection and radiant heat transfer. The 140 degree temperature of the underside roof surface drives the heat transfer process that pulls air in from all the openings in a house. And that cost you a lot of money.

Standard HomeVented attic graphic showing the natural convection process that allows air to be 'pulled' up through the house and escaping outside.

By having insulate the roof surface with spray foam, the surface temperature exposed to the attic (the temperature driving the heat transfer) is reduced by as much as 40 degrees.

Both conduction and convection heat transfer are proportional to a temperature difference, so that heat transfer will be reduced proportional to the drop in surface temperature.

Sealing the attic is the single most cost-effective solution for lower energy bills and a comfortable home.

Unvented Attic SystemUnvented attic graphic showing an insulation roof deck and air tight attic that does not allow air to escape the building.

The benefits of including the attic in the insulated space are:

- Duct leakage and heat loss/gain from ducts is much less of an issue

- Air sealing is easier in the roof than in the ceiling

- Tests show energy costs are observably lower when the attic is sealed

- "Stack effect" from wind pressures is eliminated

- Dust and loose insulation are less likely to migrate down to the living space.

Building Science Experts

Nobody understands the science of building better than .

If you want to build a thermally efficient and air tight home, it's not enough just to insulate. You must choose the right insulation and air sealing system for the application, and be sure it's properly installed.

Did you know that an improperly insulated and sealed home delivers 4500 lbs. of excess greenhouse gases into the air each year? It can also waste 20 percent or more of the energy used to heat and cool the home.

Our Building Science experts understand the principles of heat, air and moisture flow, and how the building envelope interacts with a building's mechanical systems as well as its occupants.

N.A.S.A. applied one-inch of spray-on foam insulation on the Space Shuttle's External Tank that serves to insulate the tank. The closed-cell foam used on the tank was developed to keep the Shuttle's liquid hydrogen fuel at minus 423 degrees Fahrenheit and the liquid oxygen tank at near minus 297 degrees Fahrenheit even as the tank sits under the hot Florida sun while preventing a buildup of ice on the outside of the tank.

Properly insulating and sealing your homes with Spray Foam is a greener alternative. .

We can help you in specifying the right insulation system for our local climate. Contact our Building Science experts with your inquiries at .

It is now well established and accepted by most architects and builders that controlling air infiltration is the best and most cost-effective means of reducing wasteful heat loss and providing a comfortable indoor environment.

Most architects tend to design structures that are tight and energy efficient by incorporating the latest in proven, energy saving construction details into their drawings.

Unfortunately, too many buildings still perform poorly. Why is this?

We have found that since there is no performance specification to dictate building construction, there is no guarantee when it comes to building performance. Regardless of the contractor's ability, tight buildings are not created from a list of materials and drawings in the absence of specifications that dictate the building's designed environmental performance.

takes a different approach

To improve building performance, our company focuses on the basic building science principle that air infiltration compromises the effectiveness of the building envelope. Our approach is incremental - areas of infiltration are diagnosed and fixed in order of magnitude. This provides the most thorough and cost-effective solution possible.

has satisfied clients. Our clients have been extremely pleased as they benefit from cost-savings and an immediate improvement in comfort.

We operate two-part urethane injection equipment to superinsulate new and old buildings. Included in this equipment are special nozzles and guns to seal cracks and small openings which effectively stops infiltration that cause poor thermal performance.

There are other urethane contractors who provide typical spray foam services; however, very few go beyond the installation of conventional spray-roofing and spray-wall insulation processes.

Our capabilities, while serving these common markets in some cases, are specially designed to meet the unconventional needs of specialty markets.

By employing standard and custom equipment which processes foam through both spray and injection techniques, we can utilize numerous chemical systems with varying densities, speeds, closed-cell content, fire rating, vapor permeability, and other desirable environmental characteristics.

While there may be other foam contractors who provide spray and injection services, to the best of our knowledge, we are the only company that currently uses "ratio monitoring" equipment in the field for this process. Ratio monitoring enables our technicians to maintain the exact chemical formulation (mix) for the duration of the installation process.

It is impossible to guarantee that the appropriate mix is being maintained without the use of this equipment.

Why Choose Us?

- Constant Owner interaction means no project manager or multiple people trying to make decisions.

- The highest quality products and with many small details that often go unnoticed by other contractors, let's take your insulation project to the next level.

- Quality Control. The owner is hands on throughout the project, if any problems or issues arise they can be dealt with immediately.

- Nonstop communication - The key to the success of your project is good communication. And, a big part of communication is listening. From the beginning of a project to its end, our company places a high priority on listening - to you, your needs and wishes.

- Solid Science - Our Building Science experts understand the principles of heat, air and moisture flow, and how the building envelope interacts with a building's mechanical systems as well as its occupants.